![]()

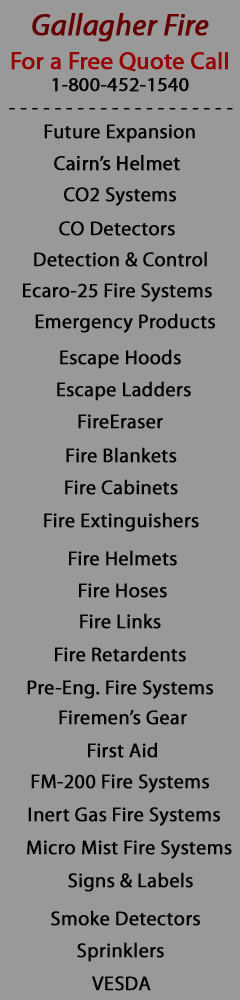

|

FireDot.com |

![]()

FM - 200

Specification:

Manufactured in accordance with DOT 4BW-450 minimum

Material: Grade 2 or Grade 3

Carbon %. . . . . . . . . . . . . . . . .24 max .22 max

Manganese % . . . . . . . . . . . . . 0.5-1.0 max 1.25 max

Phosphorus % . . . . . . . . . . . . . 0.40 max 0.45 max

Sulphur %. . . . . . . . . . . . . . . . 0.05 max 0.05 max

Ref. Temp. for Developed Pressure:. . . 122 °F (50 °C)

Developed Pressure at Ref. Temp: . . . 482 psi (33.2 bar)

Hydraulic Test Pressure: . . . . . . . . . 900 psi (62.1 bar)

Minimum Burst Pressure: . . . . . . . . 1800 psi (124.1 bar)

Thread Type: . . . . . . . . . . . . . . . 4 in. 8UN

Paint Finish: . . . . . . . . . . . . . . . Red epoxy polyester or

red polyester powder coated

Maximum Fill Density: . . . . . . . . . . 1 kg/L

Minimum Fill Density: . . . . . . . . . . 0.5 kg/L

| Valve Size | Part No: (Cyl. & Valve) | Volume: Nominal | Dimension A: Nominal | Diameter: | Empty Weight: |

| 1 in | 570003 | 8 L | 12.0 in. (304 mm) | 10 in. (254 mm) | 32.6 lb. (14.8 kg) |

| 1 in | 570004 | 16 L | 19.8 in. (502 mm) | 10 in. (254 mm) | 40.6 lb. (18.4 kg) |

| 1 in | 570005 | 32 L | 32.8 in. (833 mm) | 10 in. (254 mm) | 57.5 lb. (26.1 kg) |

| 2 in | 570006 | 52 L | 23.5 in. (597 mm) | 16 in. (406 mm) | 108.3 lb. (49.1 kg) |

| 2 in | 570007 | 106 L | 40.2 in. (1021 mm) | 16 in. (406 mm) | 158.3 lb. (71.8 kg) |

| 2 in | 570008 | 147 L | 53.3 in. (1354 mm) | 16 in. (406 mm) | 198.2 lb. (89.9 kg) |

| 2 in | 570009 | 180 L | 64.3 in. (1633 mm) | 16 in. (406 mm) | 233.2 lb.(105.8 kg) |

| 3 in | 570346 | 343 L | 57.7 in. (1466 mm) | 24 in. (610 mm) | 456 lb. (207 kg) |