![]()

|

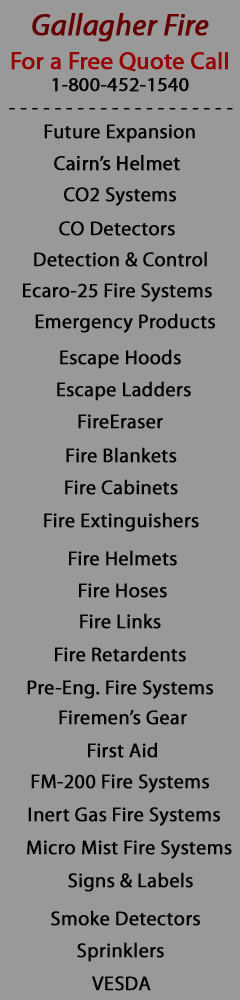

FireDot.com |

![]()

CHAPTER VI

SYSTEM RECHARGE

GENERAL

This chapter will detail the basic information necessary for recharge of the Pyro-Chem Kitchen Knight II Restaurant Fire Suppression System. However, before attempting any system recharge, it is necessary to attend a Factory Certification Training Class and become certified to install, maintain, and recharge the Pyro-Chem Kitchen Knight II Restaurant Fire Suppression System. Because it is difficult to completely understand every aspect on an intricate pre-engineered system simply by reading the Technical Manual, Pyro-Chem will not be responsible for system recharge by any non-certified person(s).

SYSTEM CLEANUP

CAUTION: Before attempting any clean up, make certain that all fuel sources to the equipment to be cleaned have been shut off. Make certain that the exhaust hood and all appliance electrical controls have been de-energized to avoid any chance of electrically shock resulting from the cleaning process of electrically conductive alkaline liquid agent and/or its residue.

Make certain all surfaces to be cleaned have cooled down to room temperature.

Do not use water to clean any appliances that contain hot grease or cooking oils. Doing so may result in violent steaming and/or spattering.

SYSTEM RECHARGE

NOTE: Determine the cause of system discharge and correct immediately before performing system recharge.

1. After discharge, inspect the entire system for mechanical damage. If the tank has sustained any mechanical damage, it must be hydrostatically tested before refilling.

2. Disconnect the 1/4 in. (.6 cm) actuation tubing or the control head from the top of the tank valve.

3. Relieve the pressure from the top chamber of the tank valve by depressing the core of the valve in the valve cap assembly. By performing this operation, the valve will close.

4. Slowly remove the valve and siphon tube. If there is any residual pressure left in the tank, it will bleed out through the pressure relief slot in the valve threads.

5. The complete piping system must be flushed after a discharge. Flushing solution, Part No. 79656, must be used when flushing the system. The solution is shipped in a 32 oz. (.95 L) container. A PCL-300 tank requires 1 container of solution. A PCL-460 requires 1 1/2 containers, and a PCL-600 requires 2 containers. To prepare the system for flushing:

- Pour the required amount of flushing solution into the tank.

- Fill the tank approximately half full with warm, clear water. Agitate the tank for a few seconds and then add more warm water to bring the level to the required fill line using the measuring stick, Part No. 551039.

- Reinstall valve and pickup tube and pressurize tank to 225 psi and reinstall to piping network.

6. With nozzle in place, attach control head and manually actuate the tank. Allow the tank to completely discharge through the piping network.

7. After the discharge is completed, the entire piping network must be blown out with air or nitrogen until no more mist is visual coming out of the nozzles.

8. Remove, clean and reinstall all nozzles.

9. Remove the tank from the system. Slowly remove the valve and siphon. If there is any residual pressure left in the tank, it will bleed out through the pressure relief slot in the valve threads. The valve and pressure regulator (located in outlet of valve) must be cleaned and rebuilt after each discharge. To rebuild the valve, use rebuilding kit, Part No. 550698. To rebuild the pressure regulator, use rebuilding kit, Part No. 551061. Each kit includes an instruction sheet listing detailed rebuilding instructions.

10. Fill tank with required amount of Kitchen Knight agent, Part No. 551188, using measuring stick, Part No. 551039. Tank should be filled to a tolerance of -0/+1/8 in. (-0/+.3 cm) from the mark level on the measuring stick.

NOTE: During filing, the agent temperature should be 60 0F to 80 0F (16 0C to 27 0C).

NOTE: The pressure gauge attached to the tank valve should not be used to determine when the charging pressure has been reached. A calibrated external gauge must be used.

NOTE: The pressure regulator in the valve outlet must be removed before pressurizing.

11. Reinstall valve and pickup tube. Pressurize Shrader valve assembly with 150 psi (10.3 bar) of nitrogen. Install recharge adaptor, Part No. 551240, into the valve outlet and pressurize with nitrogen to 225 psi (15.5 bar). Wait 10 minutes and verify the pressure in the tank is at 225 psi (15.5 bar). Relieve the pressure from the Shrader valve assembly (this will cause the valve to close) and then disconnect the recharge adaptor. Reinstall pressure regulator into valve outlet.

CAUTION: If pressure is not relieved from Shrader valve assembly before the recharge adaptor is removed, the tank will discharge.

12. Replace all fusible links by following the instruction listed in the Installation Section.

13. Reset control head (s), accessories, pull stations and gas valves by following the instructions listed in the Installation Section.

PREVIOUS

NEXT